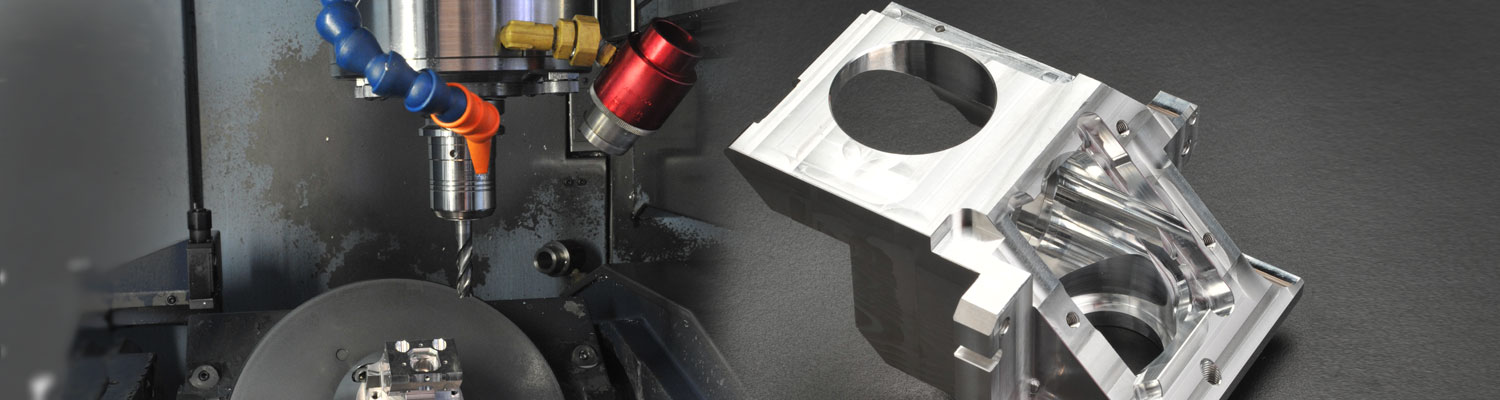

6-AXIS CNC MACHINING SERVICE

WHEN SHOULD A 6-AXIS CNC MACHINING SYSTEM BE USED?

HOW THE 6-AXIS APPROACH WORKS

RARITY IN AVAILABILITY

Because of their complexity, a 6-axis CNC machining system is not going to be an everyday tool that everyone has lying around waiting to be used. Only dedicated CNC shops are going to invest their capital in obtaining one, going through the training to run it correctly, and then set up the infrastructure to support its maintenance and long-term operation. The commitment is significant, which is oftentimes a drawback for smaller shops to invest in. They would rather stick with a 5-axis or 4-axis system instead, which takes less to operate and can come close to desired specifications, usually.

Key Advantages

When time is of the essence for highly-detailed work, the 6-axis CNC machine will shine brightly. The system works far faster than even a 5-axis CNC machine, and it produces a higher level of detail in the output product. Even when the products are evenly matched, the 6-axis system will simply be faster in terms of time taken, which can matter when under pressure to get a product manufactured by time and date certain.

A 6-axis system provides incredibly greater control when shaving is needed for small measurement changes and adjustments not possible with other machines. This is critical when layering has to be milled or trimmed off the product versus just bluntly cut at an angle, especially when a round shape or curve is involved.

6-axis CNC machining works extremely well with softer materials such as aluminum, wood, and thin steel as well as ceramics. These materials can deform under heavier applications or lose too much material, especially when friction heat occurs. With less friction and more application, the 6-axis system avoids the related problems and produces results.

Evden Enterprises has put the time and energy into providing 6-axis CNC machining services to customers, a big difference from other CNC services available. Because Evden’s teams have spent so many years with CNC systems, the 6-axis option was a natural addition to Evden’s stable of services possible and available for customers to take advantage of. Call to find out more!

LOCATION

Evden Enterprises

2000 Wellmar Dr

Ukiah, CA 95482

(707) 462-0375

© Evden Enterprises.

All Rights Reserved.

D2P Web Design

BUSINESS HOURS

| Monday: | 8 AM - 4:30 PM |

| Tuesday: | 8 AM - 4:30 PM |

| Wednesday: | 8 AM - 4:30 PM |

| Thursday: | 8 AM - 4:30 PM |

| Friday: | 8 AM - 4:30 PM |

| Saturday: | Closed |

| Sunday: | Closed |