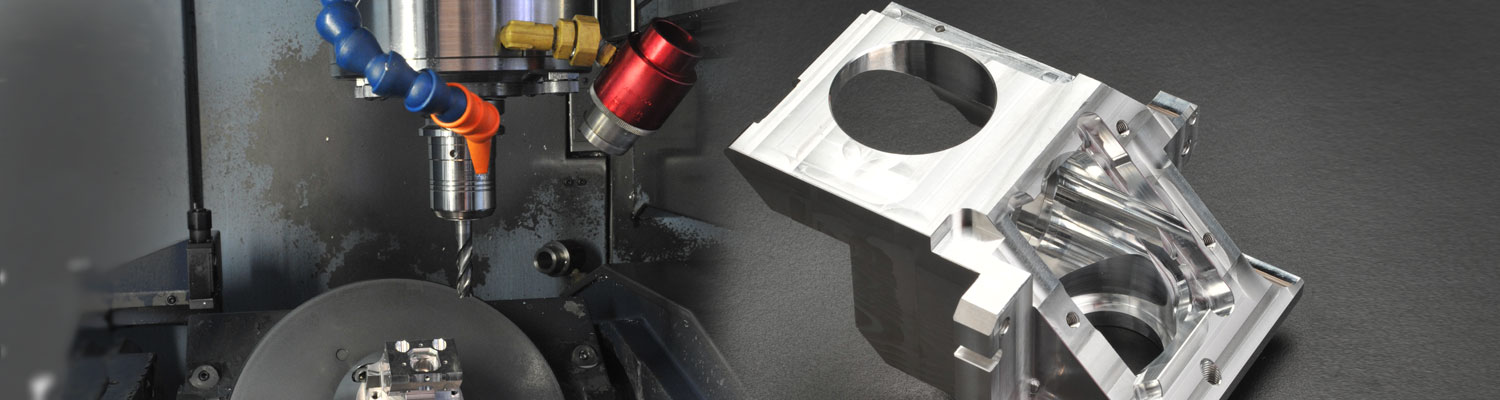

3-AXIS CNC MACHINING SERVICE

WHAT IS 3-AXIS MILLING?

THE BENEFITS OF 3-AXIS CNC MACHINING

The benefit of 3-axis CNC machining is first off the ability to create more shapes with more complex angles and directions. This provides a far more accurate representation of a computer design and specification set, and it also creates an end product that is far closer to detail specifications than just crafting from 2 axes. This is often a problem with only 2-axis machining because the system ends up having to make multiple cuts and changes to affect the same shape that is possible in a 3-axis system with one motion.

The complexity possible with a 3-axis approach also becomes very evident in the greater versatility of fabrication. Versus just producing basic parts that have to be hand-machined further, the 3-axis CNC machining is able to produce a design directly and in an automated fashion. This removes multiple steps and room for manual errors. The difference becomes immediately evident in the production of clamps, fixtures, and similar.

Easy Tool Changing

3-axis systems can still utilize tool-changers that switch out based on the programming instructions for a given design. As long as the computer has the code and the system understands the instructions, a multi-tool fabrication process is very possible. With higher-capability systems, the same design code can be used again and again with different tools instead of having to re-code the instructions all over again. As long as the script is produced from the beginning to identify which tool does what, the system will interpret when to apply the right mechanism for the right procedure.

Higher Quality Output for Tolerances

As many manufacturers have realized, top-quality one-off or short-run parts needed are met with CNC machining, and internal CNC shops in fabrication centers are commonplace. However, for the high-accuracy level, the 3-axis CNC approach has proven itself to be the standard for top-of-the-line part applications and machinery needs.

Of course, the question then eventually comes up, why not just go ahead and upgrade to a 5-axis CNC machining instead. Wouldn’t more axis produce even greater quality and output flexibility? It really depends on what is needed from the machining. For example, parts with deep insets and cavities would make sense to be made with a 5-axis approach. On the other hand, where much of the work is on the outside, a 3-axis approach provides a very efficient, high-quality output and less cost for the job. Both will produce CNC machining with far greater flexibility for designs, but one has to really scope what is going to be the primary demand for the machine work to be applied.

A key step in 3-axis CNC machining is to work with experienced specialists who know how to apply for the work as well as have the equipment to do the job right. While many can offer access to the tools, the experience is paramount to both getting the results expected as well as avoiding common startup problems. In this regard, high-quality professional external support can be a key solution for a company that needs CNC machining but may not have the resources in-house or may not have sufficient level expertise to take on 3-axis design right away.

Whatever your machining needs, whether upgrading current activities and systems or bringing in 3-axis CNC machining for the first time, Evden Enterprises can help. With years of experience in all types of CNC machining as well as an ability to competently work through new ideas and designs, our team can take on your latest demands and deliver. So, remove the ambiguity in your planning process and move a step ahead with high-quality 3-axis CNC machining. We’re your partner all the way!

LOCATION

Evden Enterprises

2000 Wellmar Dr

Ukiah, CA 95482

(707) 462-0375

© Evden Enterprises.

All Rights Reserved.

D2P Web Design

BUSINESS HOURS

| Monday: | 8 AM - 4:30 PM |

| Tuesday: | 8 AM - 4:30 PM |

| Wednesday: | 8 AM - 4:30 PM |

| Thursday: | 8 AM - 4:30 PM |

| Friday: | 8 AM - 4:30 PM |

| Saturday: | Closed |

| Sunday: | Closed |