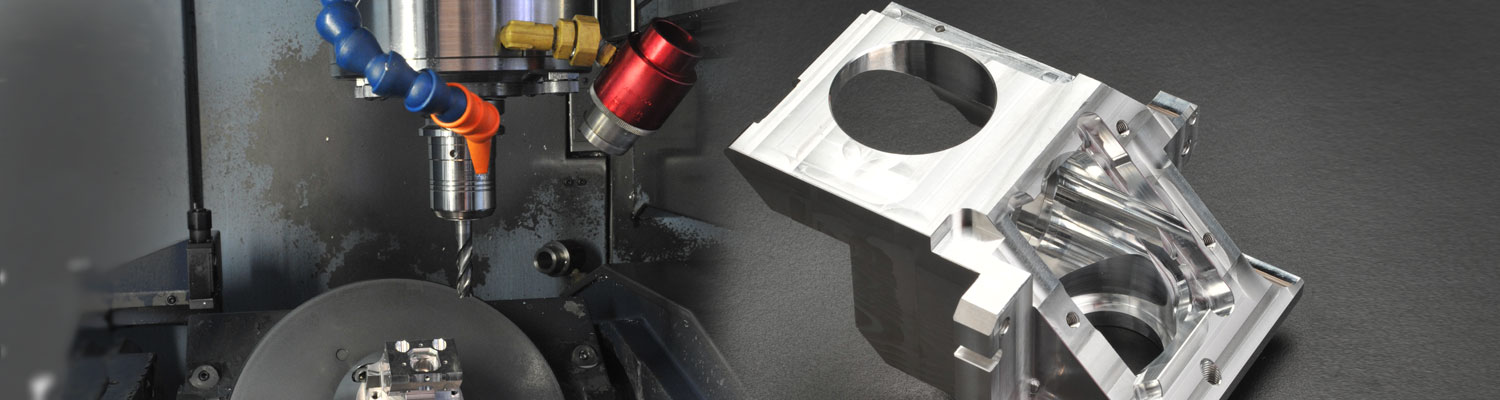

4-AXIS CNC MACHINING SERVICE

WHAT IS 4-AXIS MILLING?

THE BENEFITS OF 4-AXIS CNC MACHINING

Key factors of 4-axis work that really shine when produced by a professional CNC team include precision work, milling and lathing, and efficient shaping of unique parts that is only possible when the system can work at different angles at the same time and operation. That varies from one material to the next, but an expert CNC system operator knows the difference and can make the necessary adjustments to ensure the expected output is achieved.

Specifications on projects can vary considerably, and it takes experience to know how to address such mixes in a CNC machining application. That includes the materials that would be used, the relative hardness of the chosen material, how the finished surface should be prepared, expected tolerance and accuracy, general part shapes, and the expected waste amount. No surprise, not

MATCHING EXPERTISE TO FREQUENCY OF NEED

Outsourcing the crafting of 4-axis CNC machining work is a savvy move, especially when expert work is needed but on an occasional basis versus daily or regularly. A professional standards 4-axis CNC provider can deliver as needed with quality equipment that meets industry standards and is operated by teams with the most applicable and extensive CNC training. That avoids the problem of people learning on production work, which comes with a host of errors and waste, and it also avoids lots of time and materials spent on estimating what is needed for a new job. An expert CNC team can get right to work without a significant scale-up period or wait.

LOCATION

Evden Enterprises

2000 Wellmar Dr

Ukiah, CA 95482

(707) 462-0375

© Evden Enterprises.

All Rights Reserved.

D2P Web Design

BUSINESS HOURS

| Monday: | 8 AM - 4:30 PM |

| Tuesday: | 8 AM - 4:30 PM |

| Wednesday: | 8 AM - 4:30 PM |

| Thursday: | 8 AM - 4:30 PM |

| Friday: | 8 AM - 4:30 PM |

| Saturday: | Closed |

| Sunday: | Closed |